992 GT3 Development: Chapter 2

After a full Spring and Summer of testing and development, we are back for a (long overdue) update on our 992 GT3. Our last post shared the process of developing the exhaust suite, and those have been very popular, with lots of happy GT3 owners ripping gears all over the world! We saw great gains and a massive improvement in sound with options for each owner’s preference.

Our first track test with the GT3 was in early January (see Chapter 1). It was very cold (35*F), but dry. The car had our prototype exhaust installed, but the suspension, brakes, and wheel/tire package were stock (Goodyear Supersport R tires from the factory). We chose Pacific Raceways to do the majority of our testing for a couple of reasons: 1) It’s close, and fairly easy to get on the schedule, and 2) It’s a brutal track to test things on. It’s incredibly fast and very bumpy, with lots of elevation gain/loss and heavy braking zones. The stock(ish) GT3 proved to be immensely capable, leaving us unsure of how large an impact we might be able to make.

Brrrrrrrr!

With the exhaust dialed, we turned to the rest of the platform to see where improvements could be made. One of the first areas we found a need was the brakes. By now, it’s commonly known that the latest generation of stock Porsche pads do not perform as well as prior versions (your mileage may vary, you’ll find my personal opinion below). Our car came with Steel Brakes, but it’s pretty clear that both steel and ceramic options have different pads and are not the same experience as the 991 platform.

To remedy that, we turned to our partners at Performance Friction. PFC approached us last year and after some discussion, it was clear that our philosophies would be a great match. We received a prototype PFC Track Day Kit with 380mm rotors to test on our 992 GT3 early this year. The other benefit of switching to the PFC 380mm package is the ability to run a 19” wheel setup and gaining access to all the tire options in that diameter.

At the risk of speaking out of both sides of my mouth, I was not horribly disappointed with the stock braking performance on the track in our initial testing. The cool weather likely helped the stock system perform adequately. We also only ran one track event on the stock brakes, so my experience was limited.

That said, I was shocked at how much better the PFC package was. The first major braking zone at Pacific Raceways is before Turn 2, and the GT3 enters that segment at 164mph. Stomp the middle pedal and it’s like throwing out a parachute. Modulation is good, and the stopping power is ridiculous.

With the brakes sorted, we turned our focus to the suspension. The handling of the 992 is a huge leap for the 911 platform, that is no secret. Since the double wishbone front geometry makes the car so much better out of the box, we were again wondering what Porsche left on the table. After our initial track test, the general consensus was that while the handling was great, when pushing the limits on track there were areas that the stock dampers couldn’t keep up.

At 70% the stock system is great. But when you really lean on the car, we noticed some oscillation and difficulty handling quick transitions, especially over bumps and curbs. We partner with Motion Control Suspension out of Alpharetta, GA, USA to help us get the most out of our track cars, and the 992 GT3 is no exception. By the time we got our car last fall, MCS had a head start on the system thanks to some connections in Europe.

MCS builds great products, and their support is second to none in the industry. Their standard damper options work well, but they are a motorsport damper, built for use on track and race cars. Through extensive testing MCS and Dundon have developed a “Dundon Spec” package (this has always been the case, we have just been terrible about sharing it). This gives the car the support and control it needs on the track, while maintaining a shocking amount of streetability. These systems are all compatible with the stock Porsche Front-Axle Lift option.

This special combination was critical for the 992 GT3. The stock suspension is relatively firm, so it was important for us to ensure the car stayed well-mannered on the street. I’m very happy to share that we accomplished our goal. The car is tremendous on the track with tons of poise over bumps and curbs, with great balance and lots of grip. It also has great street manners, riding only slightly firmer than stock. The 3-way dampers have a wide range of operation, allowing for a broad range of driver-based adjustments and tailoring to different tire and aerodynamic options.

The other upgrade we made to the 992 package (and we have back-dated this to most of our other MCS offerings) is that the dampers, springs, front-lift cups and top-hats all come pre-assembled. This makes installation substantially easier and eliminates a lot of questions.

It took several test days and a few iterations to get the package where it is today. One of our test weekends involved both our 991.2 GT3 Cup (dialing in the MCS 3-way package for that platform) as well as the 992 GT3. We knew that running and dialing two cars simultaneously was going to be a big job, so we called in some backup. Mike Kojima, of MotoIQ (and circuit racing, Pro Drifting, Pikes Peak crew chief-dom), is a long time fan and friend of Dundon. Mike made the short trip up from California to help us get everything squared away. We leaned on his deep knowledge and experience to accelerate the process of dialing in both cars. At the end of the weekend, Mike drove the 992 GT3 the 60 miles back to the shop, and had this to say:

“Working on nailing down the setup on Dundon Motorsports’ 992 GT3 track suspension package. We got it down pretty good, it was the fastest street registered car on the track and the daily driving comfort is awesome! It's way more comfortable than my stock 991 GT3RS! The new unequal length A-arm front suspension works really well and Dundon has it all figured out. It is one of the best examples of streetability and no-compromise track grip ever!”

We are grateful to Mike for his help, and are very happy with the end result. We will have a separate post with all the track-data gleaned from the testing, but the verdict is in: 992 GT3 + Dundon/MCS = Track Weapon!

The final project in need of ironing out was Aerodynamics. Porsche did a LOT of work to pump up the aero performance of the 992, and there’s even more evidence of that work once you get the car up in the air and dig into things. The air is carefully managed everywhere and it took quite a bit of consideration as to how we approached improving the performance for track work.

I detailed our scanning process earlier. The scan data gave us the opportunity to run CFD analysis on the body, and any potential modifications we made. We landed on a couple of different “stages” of upgrades. The goal of these upgrades was to maximize downforce and keep the drag penalty minimized.

3d-Printed Prototype dive planes seen here:

The first stage is our Dual Carbon Fiber Dive Planes paired with our Carbon Fiber Gurney Flap. This combo is good for a 77lb increase in downforce at 100mph over the stock car (stock wing at 5*).

Production Gloss Carbon Fiber Dive Planes

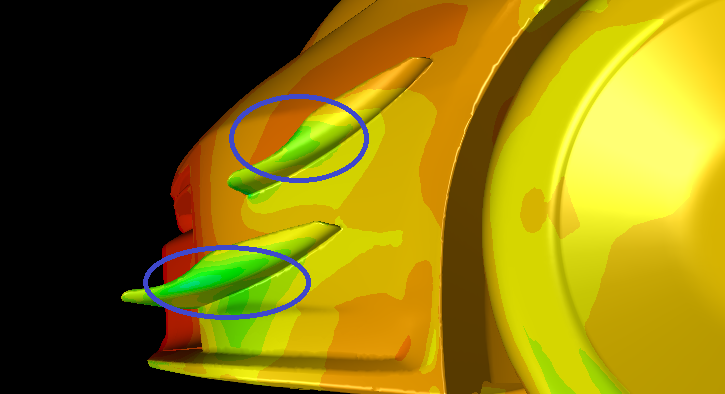

Green highlights a low pressure area due to the vortices created by the dive planes:

CFD simulation detailing the vortices generated by the dive planes:

The second combination is the Dual Dive Planes paired with our brand new “Valkyrie” Carbon Fiber Swan Neck Wing. Another project which required considerable engineering, testing and revising. This new wing profile is more efficient (more downforce, less drag) than before and is capable of producing massive downforce. It’s also “dual element ready” for the hillclimbers among us (meaning you can add a second wing element with different end plates to make silly downforce).

For our testing on the 992 GT3, we opted to run at lower angles of attack (AoA) so we ran with more downforce than the stock wing at maximum, but with less drag. This also allowed us to keep the balance of downforce appropriate so as to not induce any high speed understeer. After a couple of test days with the Valkyrie, we are very happy with the performance and balance of the car.

First track test with the prototype Valkyrie wing:

Production uprights are slightly different (wing is a little further forward):

We have plans to run the car in “higher downforce” configuration when the in-process Carbon Splitter is done and ready for testing. That package will likely require stiffer springs, because the downforce numbers are pretty healthy.

It’s fun to build parts and modify things, but it’s even more gratifying to achieve a goal. With this project, we had two major goals: 1) Make the car easier to drive fast. 2) Improve the overall performance of the car while staying true to its nature. This car is a total sweetheart to drive. It’s pleasant on the street and a weapon on the track. It’s faster than stock in the hands of a professional driver, and even more so in the hands of an amateur.

I’ll have a post up shortly with all the data sharing where the gains were made, but for now, let us know if you have questions!